| Send

items to [email protected]

for inclusion here next month.

The Treasure Chest

The Treasure Chest is a place in Reports

to put those cool sailing, cruising, motoring and boating ideas

you have. Send us your ideas... We just need a photo and a short

description.

This time we have...

| Flower Pot Heater |

|

Flowerpot heater needs a clamp of some sort for

safekeeping.

This idea came up while discussing with friends the use of a

propane cooking stove as a source of heat on boats that lack a

cabin heater. Simply firing up the stove produced little change

in heat and only increased the condensation buildup (water vapor

is a natural by-product of propane combustion). So how do you

convert an open stove flame into a more efficient heat source?

What is needed is a way to create radiant heat with minimal equipment

that can be easily stowed away when not in use. My suggestion

was to invert an unfired red clay flowerpot over a stove burner.

This will capture the heat and radiate it into the surrounding

spaces. I have successfully used this trick in a small travel

trailer, managing to take the morning chill off while making coffee

on the other burner. The addition of spring clamps or rails could

hold the flower pot in place against the boat's motion - don't

try this until you have a way to secure the pot in place as it

will get quite hot.

For materials, all you'll need is a clay pot of larger diameter

than the burner and a length of wire. A coat hanger will do the

job, but it quickly rusts. A better choice is brass brazing rod,

2mm (3/32") in diameter, available from a welder's supply

house or some hardware stores. Refer to Figure 1 for directions

on bending the wire. Note that the section marked, "Bend

up," will exert a down force on the rim of the pot, keeping

it in place, while allowing it to be easily removed when cool.

The most important thing to remember is that you must provide

adequate ventilation - the open flame will quickly deplete the

oxygen supply. To really make this safer, install a smoke head,

such as a Charley Noble, and rig a length of flex conduit as a

temporary smoke stack. This will carry the moisture and combustion

by-products outside. Conduit fittings will connect the pot and

flex pipe together. Most, if not all, vented propane stoves and

heaters use 2.54cm- (1"-) diameter stainless-steel pipe,

so the deck fitting should be compatible with your flowerpot heater.

Adding a couple of small battery-operated fans will help circulate

the heated air around the cabin.

By Ryc Rienks

A former musician, custom knife maker and teacher, Ryc Rienks

lives with his wife aboard Mai Tardis II, a Cascade 36 in Seattle,

Wash.

From DIY Boat Owner

https://www.diy-boat.com/content/view/161/56/

*****

| On Board electrical power tools |

|

On Board electrical power tools are a necessity

for boat owners on moorings and cruisers. These boaters must be

more self sufficient!

Take an old rechargeable hand drill whose permanently mounted

battery will no longer hold a charge and modify it. Often a new

battery will cost more than the whole drill did when new.

1. Remove the old battery.

2. Wire the battery terminals to a cord with a 12 volt utility

plug that will reach anywhere on your boat- or make an extension

cord. Be sure that this wiring is not compatible with 110 volt

wiring to prevent problems should someone else use it.

3. Don't worry if the drill was originally intended for less

than 12 Volt, it will work just fine and in most cases give better

service for intermittent use. If your old drill was not a reversing

motor, it can be now with the addition of a reversing switch or

plug.

This same modification can be used on any of the popular 9.6

volt or 12 volt rechargeable battery tools where it is not convenient

to recharge the battery on a 110 volt charger.

https://www.diybob.com/hottip.htm

Perspective

Mug Shot

This was done by Tom Pamperin - by the way, it is

a gag. Here is where you can put your own picture on the cover.

Chuck

February 16, 2010

Navy puts first of new tug series to work

The YT 802 Valiant, first of the new series of Z-Tech 4500 Class

tugs for U.S. Navy pilots operating in Puget Sound, was placed

in active service earlier this month.

The new series tugs are being built in Tacoma, Wash., by J. M.

Martinac Shipbuilding Ltd., a sub-contractor to Pacific Tugboat

Services of Long Beach, CA, the prime contractor.

The design was developed by Robert Allan Ltd. of Vancouver, Canada,

and adapted to the Navy's needs based on the Z-Tech 6000 hullform

originally developed for the Port of Singapore.

Based in Bremerton and Bangor, Washington, the tugs will perform

ship-handling duties for the full range of Navy surface warships

and submarines. They are equipped with an extensive array of underwater

fendering, as well as the typical resilient style fenders for

handling surface ships.

The Z-Tech 4500 class tugs have the following particulars,:

Length Overall, 27.42 m

Beam, Molded,11.65 m

Depth, Molded, 5.00 m

Load Draft, max, 4.88 m

Propulsion machinery comprises a pair of CAT 3512C, main engines,

each rated 1,350 kW (1,810 bhp) at 1,600 rpm, each driving a Schottel

Model SRP 1012 steering/propulsion Z-Drive units, with 2,100 mm

diameter fixed pitch propellers. This combination delivered in

excess of the predicted performance, providing 42 t (92,500 lb)

bollard pull ahead, 45 t (99,205 lb) astern, and a free-running

speed of 12.4 knots on trials.

Electrical power is delivered by a pair of R.A. Mitchell Co.

diesel gensets with a John Deere 6068SFM75 prime mover, each rated

130 ekW at 1,800 rpm.

Deck machinery fitted includes a ship-handling hawser winch forward;

JonRie Series 210 Assist winch, fitted with 180 m of 175 mm line.

This winch has a brake capacity of 136 t (300,000 lb), and a line

pull/speed rating of 9 t (20,000 lb) at 53 m/min (175 ft/min).

The fendering is all rated "non-marking" for dealing

with the gray hulls of warships, and was supplied by Shibata through

Schuyler Fenders.

The tugs are configured as "day-boats" but also provide

accommodations for a crew of up to six persons. One of the unique

features of the layout is the complete separation of the accommodation

deckhouse from the machinery casing, a configuration designed

to both provide a reasonably dry access to the accommodation spaces

in the notoriously damp northwest climate, as well as to provide

a significant degree of noise attenuation in the crew spaces.

Phenomenon

Dear Chuck,

Hope all is well. It was an exciting weekend at the Miami Boat

Show and just wanted to follow up in regards to Al Copeland’s

‘Phenomenon,’ the fastest boat in the world.

As you may know, ‘Phenomenon,’ 56 feet

long, 13’ and 6”, with 4 turbine engine that produce

12,000 horsepower, was built to break the world’s propelled

speedboat record of 220.5 mph.

It was created by engineers from Boeing, former US Naval architects,

& world class professional power boat builders.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The magic of this prototypical vessel lies behind the story of

famed restaurateur, Al Copeland Sr. who founded Popeyes Famous

Fried Chicken & Biscuits Restaurants and Copeland’s

Restaurants and was the former driver of the Popeyes Offshore

race team. He was a six-time National Champion who popularized

the sport of off-shore racing with actor Chuck Norris in their

Popeyes/Diet Coke race boat.

Unfortunately, about two years into building ‘Phenomenon,’

Al Copeland Sr. was diagnosed with a rare form of cancer known

as Merkel Cell Carcinoma (MCC). Just eight months after the diagnosis,

he passed away. At the time of his death, Al Copeland Sr. had

two goals he wanted to accomplish: One to find a cure for MCC,

and two to finish the boat in order to break the world record.

A southern icon, Al Copeland’s memory lives

on through his 52 restaurants, hotels, and comedy clubs throughout

the US and his Foundation,

which is dedicated to the eradication of Merkel Cell Carcinoma

Please let me know if you can run this information – really

appreciate your help!

Thank you again.

Best,

Alex and Tanya

MWW Group

[email protected]/[email protected]

Watercolors

Here's some small watercolor

sketches from last year's season.

Stacy D. Smith

Kayak by Vic

Here is my kayak so far. Had to borrow ALL the tools...etc....read

both of Nick's books....looked at tons of YouTube thingies....and

...for the first time...tried woodworking stuff. This is my Kayak

wet down after 60 grit sanding. I guess I can go up to 80...then...when

warmer weather hits...fiberglass. Totally scared about that, but...then

again, I was terrified about starting this project that was so

far out of my comfort zone....and it...ended up...so far...being

a blast. Got a bunch of exotic woods (didn't even know they existed

before)...for the deck.

G ot bad knees...don't plan on getting in it...but 5 grandsons

should have a hoot....right?

notbadforfirsttimer, Vic Druten

GIS

Good morning, Chuck,

Planning to launch my GIS next Saturday. I'm coating the hull

with epoxy today and may wait until after the launch to primer

and paint the hull. Charlie Jones and Mik both said three coats

of epoxy will protect the hull for the launch. (I have a good

reason for launching next weekend even though the boat will not

be "finished.") Skipping the primer coats this week

would free up some time for other tasks.

Pics are from yesterday afternoon.

Bob

Sea Fever to the Bahamas

Hi Chuck and Sandra

We're planning on leaving February 14 to trailer the boat to

Miami and

sail across to the Bahamas. I've started keeping a blog about

our

preparations, and once we're sailing we hope to update it every

day or

two with a little bit of news, and maybe photos if the satellite

phone

(very slow) can manage it. Anyway, you can use this site to check

in now and then to see our progress.

https://blog.mailasail.com/seafever

All best,

Garth

James Chen's Photo After a Storm

James Chen photo of boat's a'beach after the big storm......some

folks anchor offshore to avoid Santa Barbara's slip fees......we

had 13 on the beach this last weekend.

Bruce Armstrong

Stop by a Museum

Helen and I stopped by the museum today to check on the guys.

There's a lot going on, boats everywhere, sawdust in the air,

funny looking old sailors in abundance, a perfect setting. This

is what the place is all about, volunteers doing boat stuff and

having a good time. If you're tired of golf and TV go on down

and sign on. Bob showed us the cool buggy they acquired, I need

one of these. They are almost finished the huge dory they're building

for the park service. Maybe Bill Burger and the crew of Spanish

soldiers can make it across the river without the thrill of sinking

dressed in full armor when they use this one. There is an old

Star boat out front. Stars have always been a favorite with me

but this one is pretty far gone. Bob says that it all iron fastened

and every frame is cracked in at least one place. The big spritsail

skiff "Sally Adams" is getting a face lift along with

a new centerboard trunk and board. One of the benefits of working

on these boats is that you get to sail on them if you have the

nerve. Sally takes a lot of nerve when it's blowing and she's

screaming along like a freight train and Bob says " ready

about". The big Cortez fishing boat is taking a lot of work,

Smiley will be a good addition when it's finished. The second

surf boat for the Jacksonville life guards is about finished.

When you go out to see all this make sure that you check out both

shops and the museum and all of the grounds.

https://fgctsca.weebly.com/index.html

Dave

David Lucas

Lucas Boatworks and Happy Hour Club

Dugout Canoe

I am building a dugout canoe in Honduras. The

hull is 22 feet long and is hand carved from a Guanacaste tree.

The stern stems are made of Caoba which is mahogany. I am attaching

a couple pictures I thought you might be interested in seeing.

I was wondering which pintle and gudgeon set you would recommend.

I am thinking about using your rudder hardware for weekenders

because they can be mounted vertically on a narrow stem.

Greg Long

Mickey at Macy’s in Fairoaks Mall

This is a late Christmas picture of a boat I sold Jim Schafer

in November, his girlfriend happened to be the decorator at

Macy’s in Fairoaks Mall in northern Virginia. This month

St.Mary’s Children’s Home will have an auction as

part of a large fund raising gala,two of my models will be auctioned.

.jpg)

Bob has some other models in January

Reports.

Bob Guess

I’ve been busy building boats. More specifically I have

been building the Bolger Micro Trawler I wrote about last time

we corresponded. This from the guy who wrote the Duckworks 2008

article “Need

for Speed”. I blame it on my wife because

she’s the one who won’t hang her posterior over

the side of the world famous “Chuggerboat”.

That caused me to have to build a boat large enough to have

indoor accommodations. Anyway, as I continue to try to finish

her up I thought I’d send an update for your upcoming

“March Reports”. Hopefully I can send a more complete

and detailed article in the near future on the completed project.

I haven’t come along much further than the attached November

picture due to the unusually (relatively) cold weather here

in Pensacola Florida this winter. I hope to finish her up this

spring though and will report again at that time.

Pat Johnson

Pensacola, Florida

Trailer Sailer Powerboat

Just got this Dennis TS 500 its 19 ft by 7 foot beam thinking

of making it into one of those power cruising boats out of it.

It was made in Melbourne probably 20 years ago. I hasn't been

in the water for ten years and I don't know what the sails are

like.

Cheers Stewart

Fishing Boats on the Clarence

I am amazed by the number of old style sharpies professional

fisherman use on the Clarence River, NSW, Australia, so I took

a picture of one.

|

This is a fairly typical design with quite a

raised bow. |

This is a punt made of aluminum planks edge welded. No need for

internal frames it seems and the hollow planks give some buoyancy.

While we are on professional fisherman, this photo was taken

at Iluka, NSW. It's not faked. He was up on that ladder looking

for fish. The picture doesn't show it was blowing 40 knots with

rain showers.

Mike John

NorseBoat 21.5 Cruiser Press Release

NorseBoat 21.5 Cruiser Hull #1 Underway

NorseBoat Limited Prepares For Spring 2010 Production

January 29, 2010, Belfast, Prince Edward Island, Canada - NorseBoat

Limited has begun construction of their much anticipated NorseBoat

21.5 Cruiser. Hull number one is currently being built at their

Lunenburg, Nova Scotia shop using modern wood/epoxy construction.

Subsequent production NorseBoat 21.5 Cruisers will be constructed

using a high quality glass/wood/epoxy composite. Optional all-wood

construction will also be available.

The NorseBoat 21.5 Cruiser is the largest in NorseBoat’s

line of high performance sailing and rowing craft. Her sisterships

include the popular NorseBoat 17.5 Cruiser and the recently launched

NorseBoat 12.5 Cruiser/Tender. These versatile, trailerable daysailers

and camp cruisers have earned the reputation of “the Swiss

army knife of boats.”

NorseBoat founder and president Kevin Jeffrey developed the design

for the NorseBoat 21.5 Cruiser in cooperation with Mark Fitzgerald

of Fitzgerald Marine Architecture, Camden, Maine. Mark drew the

lines of the NorseBoat 17.5 Sailing & Rowing Cruiser while

working at Chuck Paine Yacht Design.

Production of the NorseBoat 21.5 Cruiser is proceeding on the

strength of five initial orders and strong consumer interest in

a NorseBoat of this size.

The NorseBoat 21.5 Cruiser has distinctly NorseBoat lines and

features, plus interior accommodations for two adults and two

children, a self-draining cockpit, and innovations unique to this

design.

The sail plan is a high performance, easy to handle cutter rig

with fully battened mainsail, signature curved gaff yard, pivoting

carbon mast, self-tacking jib, and optional furling drifter/reacher

headsail.

Customers can choose the standard ballasted centerboard or optional

low-profile fixed keel. The fixed keel option can temporarily

replace the centerboard when sailing in deeper waters or keeping

the boat at a dock or mooring. The NorseBoat 21.5 Cruiser is strong

yet lightweight, has a seaworthy hull shape, shallow draft, some

rowing capability, and is trailerable and able to be towed with

a normal vehicle.

The pre-production price is CN$29,995 plus trailer and options

for the NorseBoat 21.5 Cabin version, and CN$24,995 plus trailer

and options for the NorseBoat 21.5 Open version (no cabin).

NorseBoat 21.5 Specifications

LOA (on deck) 21’-8”, 6.60m

LWL 19’-7”, 5.97m

Beam 7’-1”, 2.16m

Draft (board up) 0’-9”, 0.23m

Draft (board down) 3’-10”, 1.17m

Draft (fixed keel) 3’-0”, 0.91m

Mainsail area 143sf, 13.28sm

Jib area 54sf, 5.02sm

Drifter/reacher area 120sf, 11.15sm

Mast height off water 22’-0”, 6.71m

Lightship displacement 1280lbs, 580kg

Rowing stations 1

Berths (1) V-berth, (2) quarter-berths

Propulsion electric or gas/petrol outboard

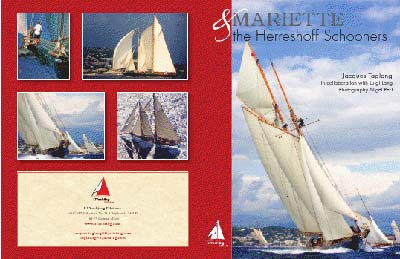

MARIETTE and the Herreshoff Schooners

Dear friends, colleagues and sailing enthusiasts,

Here is a short mail to inform you of a new book, soon to be

published, by Jacques Taglang and myself, in collaboration with

Luigi Lang.

Also attached is an order form offering the opportunity to acquire

this, our latest work, at a special pre-publication price.

With my best wishes to everyone for a happy and healthy 2010,

yours sincerely,

Nigel Pert

BASE : 00 33(0)233640591

MOBILE : 00 33(0)614906779

SKYPE : nigelpert

MAIL : [email protected]

BLOG : https://nigelpert.wordpress.com

WEB : www.nigelpert.com

******

|