|

click

thumbnails to enlarge |

There comes a time when you need to build a boat. You

drive down a road or track and as you crest a rise you

see a lake that screams out “ Here I am, come and sail

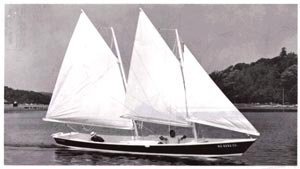

me”. This is the tale of how and why a 31’ Bolger

folding schooner started its life sailing 400 km’s from

the sea in one of Australia’s driest cities.

A GEOGRAPHY

LESSON

|

Lake Lefroy with landyacht |

Every 10 years or so inland Western Australia

gets a “25 year flood”. Great big cyclones come in,

one after the other, Out of the Timor Sea via a detour

into the Indian Ocean. They dump a few years of rain

in days, or even hours. Our annual rainfall is supposed

to be 6” but we can get local storms of 6” in 1 hour.

The eastern parts of Western Australia are very flat

with ancient river and lake systems that are normally

saline and dry.

|

Brown Lake and a flash flood

|

After such rains lakes up to 10’ deep

can appear overnight and live for 1-2 years. The biggest

is Ponton Creek, 250 km’s of swamps, rapids and salty

lakes which can flow for 3 months as it drains into

Lake Bunderoo on the Nullarbor Plain. The creek gets

a salty layer of foam up to 1 metre deep in the wilder

parts. The river system was navigated in the floods

of 1976 by rubber ducky.

Our local lakes around Kalgoorlie include

Kopai, Brown, Red, Gidgee, King Of the West, And our

beloved Rowles Lagoon. Most are 1-2 kms across. But

Brown Lake is 1.5 by 7 kms and 4WD access only.

FINDING

THE IDEAL BOAT

I started my search for a boat before

we had internet access, so it was magazines only.

Criteria was:

-

1 Open boat. Reason: When people disappear

into a cuddy cabin they tend to get sick, or suffering

boredom.

-

2 Simple to build of course.

-

3 Suit growing family. The family

was 2 adults and four girls when we started. Add

1 more girl before it was finished. Don’t forget

they have friends as well.

-

4 It has to be built in an 18‘ long

building space, along with running a small business.

No worries.

-

5 Has to be as narrow as the 4WD for

towing, with no protrusions to snag on trees when

winding through the bush. 20’ towing length max.

-

6 $6000 Australian to spend

|

click

to enlarge |

All this told me I needed lots of boat.

A cat was out as all the designs were too wide. Couldn’t

find any tris under 24’. Things were looking grim. We

might have to stick with the Hobie14 and only take a

few kids at a time.

I’d given up buying magazines as it had

cut into the budget and was down to reading them in

the newsagents. I spotted a story in ‘Watercraft’ magazine,

which featured a photo of a huge long schooner ghosting

along with a relaxed crew sprawling around the deck.

The caption said “31’ folding schooner”

I thought Hmmm…….., my wife said “Too

big . Oh it folds! OK. Two weeks later the plans arrived.

Shopping for parts involved finding plywood, glues,

and timber by phone and fax, then driving 600 km’s to

pick it all up. Just like that.

LETS BUILD

A BOAT

Since I was ready to build the boat, I

had to knock out a few other jobs first., namely a couple

of billy carts and a parade float, repair a car or 2

, renovate a bedroom………

5 MONTHS

LATER

|

The

float |

I drove the float into the shed (my 4WD

is inside the float) and pulled it apart. Before anybody

could find a use for the space in the shed I set up

the trestles and started marking out the first sheet

of ply. Bulkheads came flying out in rapid succession.

The forward hull was simply a case of

following the instructions and it turned into a hull

in no time. A handy hint: 4 house bricks in a milk crate

is perfect for holding up sheets of ply when assembling

the hull sides.

It was at this point that I learnt about

metric and imperial(s) measuring systems.

CHECK YOUR

MEASURING TAPE

clamped

bulkheads |

I started school with imperial measurements

and just as I was getting confused we changed to metric

in grade 5. The plans were in Imperial, for which Mr.

Bolger apologised, but said the design was a 1973 one

and not worth redrawing.

No worries. I soon figured out the feet,

inch, eighths, and ignored the little + and – all over

the plans. The for’ard hull was built and looked good

but not right by the tiniest amounts. At this point

the Library found me a copy of Payson's “How

to build the new instant boats” and he explained

that the + and – was + or – 1/16 “.Oooops.

This explained the unique flare in the

bow.

Have you ever heard of Japanese Inches.

The little buggers have their graduations in 1/10 Inch.

My beautiful new stainless steel metre rule featured

this sneaky variation without telling me. It took 4

hours to re-measure the ply sides of the aft hull when

I did a re-measure of a couple of spots that didn’t

feel right.

The offending part of the rule is now

painted over.

After the for’ard hull was built it was

primed and hoisted into the rafters of the shed and

I started on the spars. This was because my cash flow

was not conducive to the boxes of screws needed for

the aft hull. The booms and gaffs were done in a day

then the search began for suitable mast wood.

|

Junebug |

Kalgoorlie has 2 salvage yards. They both

work on the same principal. As buildings are demolished

anything of real value is shipped out to the capital

city (Perth) and the rest is sorted and left to rot

away due to the absurd prices being asked. I was searching

for 4 of 4”x 2” by 15 -16’ long. “Good luck” was the

reply at one yard. In all this mess I found 2 of 4”x

2”x 14’ long Douglas fir, almost clear, no cracks. They

had been part of a roof frame and were very dry on the

outside. With a lot of planing I had just enough wood

left to laminate a 3”x 3” mast . The top 1’6” came from

an off-cut from a 12 x 2 floor support of an old hotel

being renovated. The other 20’ of that beam had been

removed by a demolition crew and used in landfill!

The mast was a bit twisted so when I clamped

it about 60 clamps were used, all but 30 scrounged from

local builders and friends. Planing and sanding

took only one day , but what an enjoyable one it was.

Wading barefoot through a thick layer of aromatic shavings

is a rare delight for anybody working with wood. I suspect

finding wood for anything bigger in this part of the

world would be a true challenge. Wood cost for this

mast was AUS $40.00. Not too bad.

A week later the man from the “Good Luck”

yard rang and said he’d found a couple of sticks in

a roof. I arrived to find 2 superb pieces at 16’6” long,

not too dry, no splits, no twists. He informed me they

would cost AUS $20.00 for the 2 so I paid up and ran

for home real quick.

The next mast was to be 14’6” and the

wood was easily prepared, glued and clamped the same

day . In contrast this one needed only 30 clamps. The

finished mast is 2/3 the weight of the main mast yet

only 1’6” shorter.

After 10 months of building the cash flow

dwindled again and I had to walk into the shed each

day and not build boats, but, as if by magic ………

|

Junebug

with sails |

I was removing an old shed from a property

and when we lifted the roof off there in the crap and

rat poo was the distinct shape of a14’ Bolger June Bug

and my job was to remove it. For the next month I was

able to experiment with alternative glues, Bilge Keels,

poly tarp sails( love them), and rudder/tiller arrangements.

The result was a Bilge Keeled, ketch rigged JB with

a Thames Barge style sprit sail main, lug mizzen with

Boomkin, and the fanciest tiller and seats in town.

The boat, with its expanded seating room

was for 4 kids or 2 adults. This made me feel really

good about my choice to build the 31 footer.

Poly tarp sails were both easy to make

and surprisingly good to sail. A couple of hints:

-

1. Have plenty of reinforcing around

the eyelets.

-

2. Don’t waste your money on double

sided tapes. Use old fashioned contact adhesives,

but not the Gel types.

BACK TO

THE SCHOONER

|

jarrah hinges |

Work progressed slowly on the rear hull.

Having read a bit about the folding schooners failings

in the hinge plate and chine latch areas I started thinking

about how to beef it all up. The for hull had had 20mm

thick ply plates glued and screwed under the decks and

the chine latch area had its scantling doubled.

This was followed through to the aft hull

, particularly as the bilge boards would run through

this area too The boards were beefed from 12mm to 20

mm. All framing in these areas were increased and extra

framing added to the face of the bulkheads. I felt confident

that this would increase strength without adding too

much weight

The chine logs in the midships area were

enlarged to 3” x ¾” over the length of the bilgeboard

cases to fit wider latch plates in 3/16” Stainless steel.

All through bolts were ½” SS instead of the designed

3/8” galv coachbolts.

|

jarrah hinges |

The transom was another area that received

my attention. The designed transom seemed weak in my

eyes so the lightly framed 6mm ply was replaced with

a solid 1 ¼” Maranti slab recovered from an old security

door. It had been the back door of a house, which we’d

bought to renovate. Although this is nothing to do with

boats I was told that the owner was a retired brothel

madam, and very ugly to boot, and that the house had

once been a Fire Station in a nearby town.

Just a bit more Kalgoorlie history to

add to the boat.

The transom was the only area to be sheathed

in Epoxy and cloth. This was a very time consuming exercise

and I would dread doing it to the whole boat.

I now felt confident it would be strong enough. In motoring

trials it had a short shaft 8hp motor hung off it, as

opposed to the recommended 4.5.

The boat would be fine with a 4.5 though

as long as you were not it a strong tidal area. I would

prefer a long shaft though. (all hail the designer for

he knoweth best).

18 months into construction I ran out

of ply and money and GLUE.

|

deck plates |

When I purchased the ply the plan was

to buy enough for the forward hull with a few spare

sheets. By very careful cutting and butt-jointing some

of the smaller components I had managed to get most

of the rear hull built as well. I needed 2 sheets for

the aft bottom to finish the job.

Prices had gone way up and the original

supplier wouldn't even ring back, same with my epoxy

supplier.

A pine marine ply was ‘available‘ locally,

i.e. pay the $110 and get what comes on the truck.

I went back to the boat and worked on

stainless and wooden fixings, a couple of 10’ oars,

some extra ribs for the floor of the boat. Even some

Baltic Pine flooring that I’d rescued from a skip at

a local hotel.

This went on for a few months as Christmas

approached. When my father in law arrived with the kids

Christmas gifts , there in the back of his Ute was a

beautiful sheet of ply, Thank you Norman.

He’d gone out to buy 2 but was caught

out by the “Special Discount” prices being offered and

could only afford 1. As the 2 bottom sheets had to be

joined BEFORE fitting to the bottom I now had to watch

a sheet of ply slowly twist and buckle and check in

the hot dry Kalgoorlie summer.

|

My

version of a solid transom |

A friend who would be crew came to the

rescue by buying a sheet of the same pine ply and dropping

it in my shed whilst I was out. So that night

it was all on for young and old as the bottom went on.

The keel and bottom runners had been cut and waiting

in the wings for some time. The keel had previously

been a doorframe in a house in a nearby town and came

to me via the towns tip.

The bottom logs are another story. Part

of my job involves cleaning out yards and sheds in rental

properties. Every now and then I have to remove broken

or discarded furniture. The best of all is the Futon

bed, you get a huge bundle of long square or rectangular

slats of really well seasoned and springy wood. In Australia

they tend to be a wood known to us as Ramon? Normally

they are double bed width as a bonus.

Hint - check out the local second hand

stores for these babies. I used wood from 2 beds and

still have a huge bundle of 1” x 3/4” staves.

Anyway back to the boat.

Before the final coats of paint went on

I decided to build the trailer so that I could slip

the hull on and off to get it right, without scratching

the paint.

THE ART

OF BUILDING A TRAILER

Having rung a few trailer

manufacturers it was apparent that that a new one would

cost more than the boat. The problem with shopping for

a secondhand one in Kalgoorlie is that you are nowhere

near the sea, i.e. no boat trailers for sale.

Once again my beloved rubbish tip saved

the day. Whilst dropping off a load of garden waste

I spied an axle with wheels and springs still attached.

I had to actually pay on this occasion, $25.00 was a

bargain though. The heavy gauge angle was in piles around

the yard and whist driving down a track I found a pile

of off-cuts that had literally fallen off a speeding

truck. The 2 biggest pieces of 4”channel were just the

right length for the trailer that I had planned.

All the rollers came from the remains

of our old Hobie trailer. I bought a NEW tow hitch.

Time to build was 2 ½ days welding and less than $100.00.

And we were rolling.

Meanwhile painting started again. As the

boat wasn’t going to be glassed I opted for lots of

coats of paint. 2 pink primers, 2 undercoats, and 2

gloss enamels. The finished hull in Sunset red was ready

to join and rig.

Funnily, on the launch day photos, the

colour of the boat was the colour of the sunset!

OH NO NOT

THE SAILS!!

Now that the boat was out of the shed

and sitting on the trailer in my wife’s carport I had

a large space in my shed . In situations like this it

important to act quickly. If the wife and kids get a

chance to get any jobs in the space I would be doomed.

I gave the floor a good clean and unrolled the polytarps

that I had to hand.

For the next 2 nights I was in the shed

covered in glue and off-cuts creating 3 sails. These

were then led lovingly into the house and stacked next

to my wife’s most cherished possession, the Janome.

She’d agreed to sew them after I completed a list of

jobs around the house and a 2 day baby-sit so she could

swan off to a conference.

The experiments with the June Bug had

paid a dividend as the whole process of cutting, glueing

and sewing went very smoothly indeed.

LETS RIG

A BOAT

As I began rigging the boat I realized

where the cleverness of the designed rig was starting

to show. All the rigging was to be 6mm silver rope.

I rang around a few marine suppliers and hardware discounters

and found that the best price was at my local hardware

store. The marine guy tried to convince me that I would

have to use 6 mm spectra all round. I explained that

the gaff sails were only 65 and 95 square ft with 2

lines each, but he wasn’t sure what a gaff was . He

didn’t recognise the word Marconi either, Kids today!

The boat uses 124 metres of 6mm line for

the running rigging, and reeflines, and Parrel lines.

This left 1 metre on the roll. I would have liked to

leave an extra metre on each of the halyards though.

It took 2 days to cut, whip, and colour code all the

tips of the lines. All the snapshackles were from the

hardware store labeled as dog lead snap clips, in chromed

bronze. Identical to the marine ones but at 1/3 the

price.

It was a real buzz to hoist one sail after

another on new lines and get comments from passersby

as they realized there was a ruddy great boat in a driveway.

After almost 2 years I was able to step

back and look upon this beast that I’d built and start

to realize its potential. When you’re at the helm you

have to shout to the kids at the bow to give them an

instruction. This boat was just like everyday life!

|

Un-folding sequence |

THE LAUNCH

The day of the checklist was here:

Remember all those cyclone filled lakes

that appeared overnight? They were all dry except

for one, Rowles lagoon.

It is 100km’s of mostly dirt road to the

north of Kal. And a fresh water lake to boot.

With friends and family in tow we headed

out for the big weekend of sailing. On arriving at the

lake everybody got down to the task of lighting fires

and putting the billy on, but I was in a hurry. I backed

down into the water and shoved the folded boat off into

the water. It immediately caught the breeze and swung

back into the trailer mudguard and 20 seconds in I had

my first hole. This all caught the attention of my fellow

campers who now started to gather to WATCH. I explained

how we were going to unfold it and explained that they

would need to take off their shoes, roll up their trousers

and join me in the 10degree water. With a team of 4

we unfolded the boat and the shear size of her became

apparent to all.

Rigging on water for the first time was

a surreal experience. I counted as many as 11 kids at

any one time, oars were going in, out and around, my

daughter produced a Cornet, and became a brass band

playing “Waltzing Matilda “ of course.

The first “Man overboard” occurred in

6” of water with the bow still ashore. The kid involved

just climbed back in and got my cushion wet.

I suppose a bloke would start getting

grumpy and snarly at this point, but I reminded myself

that this was what I’d built it for.

|

Rigging with Band |

Sailing the schooner was much like any

big dinghy. Just get in and go, but remember how long

you are when you need to turn. The Tiller is surprisingly

light and responsive and has about 2 –3 degrees of leeway

when the wind is up.

Day 1 was sailed with Jib and main in

20 – 25 knots on flat water, with a crew of 3 adults

, 3 kids.

Our family were the only ones camping,

so the next day saw me and 5 kids with jib, fore and

reefed main. Day 3 was superb, same crew with a light

breeze, all sails full and bye.

The wind increased over 2 hours to 15

knots. We all had a ball that morning. I found the way

to sail was to lay in the bow and let the kids do it

all. My 8 year old was the best of the helmswomen, and

was even able to steer up onto the beach area we had

cleared of rocks whist I bellowed commands to lift boards

and lower sails.

FOLDING

BACK UP

This was going to be a challenge due to

the fact that there was only my wife and I to accomplish

the task. In honesty, I wouldn’t try it again without

2 strong adults, preferably tall. Whilst we could do

it there was a high probability of someone slipping

and injuring a back or even damaging the boat (heaven

forbid) as it was we took 3 tries to get our stance

and grip right. Whilst aborting the second attempt the

pulley on the traveler/hinge pin dropped into the closing

gap between the hulls, forcing them apart and damaging

the hinge. I am now working on some kind of side mounted

hoist to fold and unfold the boat before launching.

Despite the size and weight of the boat I was able to

push it onto the trailer without a winch.

******Setting sail – Note size of helmswoman******

|

Setting sail – Note size of helmswoman |

CHANGES

I MADE TO THE DESIGN

1. I added a slotted inwale to the rear

hull. Initially I was concerned about side flexing

over the long length of the cockpit. Later I was pleased

to see that the inwale was ideal for fitting removable

rowlocks and a great handhold for the kids.

2. I built the bilgeboards at ¾” thick

instead of the designed ½”. This was due to experience

with the rudder blade. The first rudder blade was

½” with 6oz cloth and epoxy on each side. It used

absurd amounts of the liquid gold and still had way

too much flex. I didn’t even bother to fair it up.

The ¾” MDO rudder as built in only 1 hour and feels

very stiff. It hit a tree stump after 1 hour of sailing

with no damage.

3. The rudder/tiller assembly was changed

to a regular tilt up arrangement with a normal tiller.

The designed set up didn’t work very well when we

tried it on the June Bug and I found pushing and pulling

a pole instead of a tiller quite off-putting. The

original design was probably intended for when the

skipper had to be well for’ard when sailing.

|

floorboards |

4. Extra ribs of 1”x 3/4” Ramin were

added to the rear hull (futon bed slats), 2 between

each designed frame. This stiffened the hull sides

and floor quite nicely.

5. I made a series of removable floor

panels of Baltic Pine floorboards (the Australia Hotel

verandah, and the Mt. Lyall hotel top landing). These

get stomped on, jumped on , lifted out and used as

a picnic table and a camp bed.

They are varnished with a light sprinkle of sand for

grip. One effect is that there is now a huge

expanse of varnished wood running the length of the

otherwise painted boat.

WHAT WILL

I DO DIFFERENTLY NEXT TIME

1. ½” ply for the bottom of both hulls.

When I damaged the side of the boat it was so easy

to do. I’m very cautious when beaching.

2. Buy all the ply and epoxy when I

start and not as I go along (perhaps even the sails)

3. I think you need to build some strong

points under the decking of the Bow and Stern to take

anchoring and mooring cleats. Possibly some kind of

Samson Posts.

4. More clamps! I had 20 of 3”, 8 of

8”, 2 of 24”. You need more 8” and more 24”.

MY TOOL LIST

-

4” power plane

-

10” hand plane

-

4” belt sander

-

Handsaw

-

91/4 powersaw

-

reversible 240v drill

-

reversible 14v drill

-

handdrill

-

carpenters hammer

-

¾ chisel

-

3/8 hollow gouge

-

jigsaw

-

mall router (borrowed as required)

-

Hand mitre saw(I was given a power

one after almost finishing the boat)

-

12” drawknife

-

4” grinder fitted with stone grinding

disc

-

1” putty knife

-

3”flexible putty knife (little devil)

-

carpenter’s square

-

bevel guage

-

6” surform

-

26’tape

-

1 metre rule

-

100 litre beer fridge

-

big huge stereo speakers in the shed

If you have any queries please feel

free to Email me at:

[email protected]

If you’ve ever sailed, seen or owned a

folding schooner I’d love to hear from you. Paul Day

AUS3 “Waltzing Matilda” Kalgoorlie Western Australia

P.S. Just as well I built a big boat as

daughter number 5 came a long just prior to finishing

it.

|